Many commercial and military marine facilities rely on floating camels for various berthing and nesting operations. These floating camels are also known as fender camels, camel logs, fender camel logs, float camels, and navy camels. These devices provide a standoff distance between vessels and piers and can also be used to distribute vessel berthing load across several fendering pilings. Different types of ship camel designs perform different functions for a variety of applications.

At Marine Fenders International, Inc., we design and manufacture a selection of OCEAN CAMELS™ featuring high-quality designs. Our floating camels are the best in the industry, available in multiple materials and providing fantastic buoyancy and strength for any application. Whether you’re looking for ship-to-ship berthing, berthing load distribution, stand-off distance creation between vessels and a pier or any related need, our floating camels products will get the job done. Contact us today to learn more!

About OCEAN CAMELS™

Our OCEAN CAMEL™ products are composite floating camels that provide standoff between piers and vessels. In addition, their design makes them suitable for distributing forces over large lengths of pier structures to mitigate the risk of point loads. They’re available in several composite materials, which provide a positive buoyancy camel with superior strength. Available options for each design include deck fittings, decking, rendering, colors, and additional buoyancy, among others.

The Navy uses many floating camels made of large, heavy steel structures. Our floating camels can serve this large barge type of work with our innovative camel designs. While many mistakenly believe that floating camels are primarily made of timber or plastic, our navy carrier camels feature more sophisticated designs.

Marine Fenders International, Inc. manufactures a variety of composite constructed Ocean Camels™ which are designed for a variety of applications, including:

- Providing a desired stand-off distance between vessels and a pier

- Distributing berthing loads across several pier piles

- Ship to ship berthing and nesting application

- Paint and maintenance camels provide a safe working platform

- Navy submarine camel provide safe berthing solutions

Ocean Camel™ Products at Marine Fenders International, Inc.

DDG – Ship Separator

Our DDG ship separator nests U.S. Navy Arleigh Burke-class destroyers. We use square tubing to construct these floating camels in place of angle iron. This separator features four 6′ x 12′ fenders containing foam to facilitate flotation and energy absorption. These floating camels are also offered in other sizes and configurations for commercial and military applications. All sealed areas are 100% filled with closed-cell foam.

Learn more about Marine Fenders International’s ship separators here.

LC – Camel Logs

Our LC Camel Logs are utilized for Navy and commercial facilities. Ocean Camel™ Logs are composite cylindrical floating camels designed to provide standoff between the vessel and the pier. Additionally, they are designed to distribute forces over a larger length of the pier structure to avoid point loads. They are available in two designs.

- Ultra-high strength steel pipe core, which is filled with closed cell urethane floatation foam. It has a thick outer tough abrasion resistant, non-marking urethane wear surface. It is available with dual hawse pipes or swivel end fittings.

- Plastic pipe core type is filled with urethane foam and constructed with dual hawse pipes.

Learn more about Marine Fenders International’s LC-Camel Logs here.

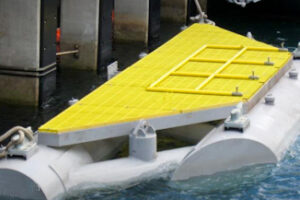

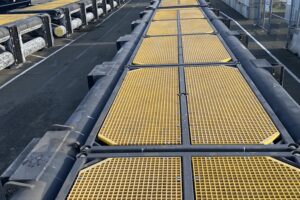

CPC – Composite Plastic Camels

Ocean Camels™ are available in a barge type construction with numerous designs, configurations, and constructions. These floating camels are constructed with reinforced plastic timbers and closed cell buoyancy modules if needed. Options include non-slip decking, deck fittings, colors, fendering, additional buoyancy as well as other options.

Learn more about Marine Fenders International’s CPC -Composite Plastic Camels here.

SSC – Surface Ship Camel

The SSC surface ship camel berths CH and DDG class surface vessels. These floating camels feature a sealed tubular steel design containing 100% filled closed-cell foam, and non-marking grey fenders which will not damage the ship’s hull coatings. Also, they have an improved anti-fouling coating, along with 316 stainless steel hardware that lends a longer service life and reduces maintenance requirements. The standard SSC camel is an ideal working platform as it possesses a 10 ft by 40 ft composite decking. The length of the SSC provides load distribution over multiple piles. The SSC surface camel is customizable to suit our clients’ special applications.

DDC – Deep Draft Camel

Our DDC floating camels are available in 2 basic designs.

The DDC-FA camel helps berth U.S. Navy fast-attack submarines. This lightweight design includes seal-welded tubular steel with open bottom pipes, submarine side fenders that are vertically positioned, a narrow berthing footprint, and a wide body design. All sealed pipes are 100% filled with closed cell foam.

The DDC-AC camel is used to berth all classes of submarines.

This robust wide-body design provides appropriate load distribution along the pier while also providing a narrow contact footprint on the submarine. This design minimizes contact to sensitive areas on the submarine. All seal-welded tubular steel is 100% filled with closed cell foam. The deck is designed with a large composite working platform.

UTS/CSS – Universal Triangular & Cylindrical Submarine Separators

Both the universal triangular submarine separator and the cylindrical submarine separator feature composite floats that are designed for rapid deployment. All tubular steel is 100% filled with closed cell foam. The universal triangular submarine separator consists of a composite float that supports a steel triangular frame that is lined with rubber fenders. The cylindrical submarine separator also consists of a composite float that supports 3 cylindrical rubber fenders hung vertically in a triangular configuration. The universal triangular submarine separator provides a greater standoff than the cylindrical submarine separator.

Advantages of OCEAN CAMELS™

OCEAN CAMELS™ offer several key benefits that make them ideal for many applications, with advantages such as:

- High strength and impact resistance

- Positive buoyancy

- Composite construction

- Spreads berthing loads across fender pilings

- Abrasion resistance

- Extremely low maintenance requirements

- Non-slip decking

Choose Marine Floating Camels at Marine Fenders International, Inc.

Marine Fenders International, Inc. is an innovator of marine rendering solutions and buoyancy systems in the marine industry. Our portfolio of ship floating camels includes advanced engineering designs made with the appropriate materials for each design and advanced polyurethane elastomers that offer superior durability and strength. Our team has over 30 years of experience in the marine and polyurethane industries, providing our customers with top-notch solutions. Our state-of-the-art facility and manufacturing processes also enable us to provide top-quality products at some of the lowest prices available. Additionally, we work to continually improve our processes and products to keep up with the ever-changing needs of the marine industry.

Marine Fenders is also a member of the American Standard and Testing Methods (ASTM) Fendering Task Group, which helps advance marine rendering specifications into the next generation.

For more information about our line of floating camels, contact us today with any questions you may have. To get started on finding the ideal solution for your application, request a quote.