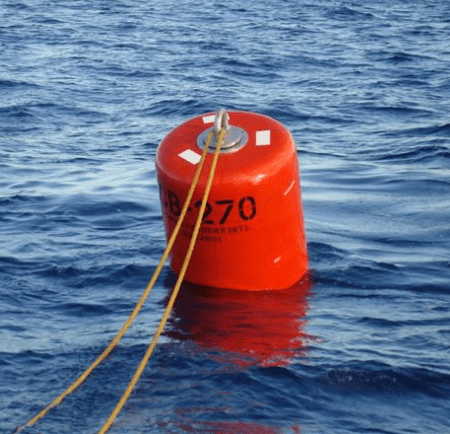

Marine Fenders International, Inc. manufactures high-performance marine buoys for use in ports, harbors, coastal waterways, and offshore installations. These products are built to function reliably in demanding marine environments, where long service life and low maintenance are critical. The company offers a wide selection of foam-filled, steel-reinforced buoys, developed through experience with commercial operators, government agencies, and military clients. Waterway buoys produced by Marine Fenders International contribute to safety, vessel control, and infrastructure protection across a wide range of marine settings.

Ocean Guard™ Series Overview

The Ocean Guard™ line includes buoy designs suited for mooring, anchoring, channel marking, and support functions. Each buoy is manufactured using a closed-cell foam core that prevents water absorption that is keeping them afloat even if the outer skin is damaged, helping prevent failure. The outer skin is reinforced with nylon tire-cord and constructed from a durable elastomer, allowing it to withstand repeated vessel impact and weather exposure. A central steel core or internal steel components provide strength and connection points for mooring lines, chains, or fittings. The Ocean Guard™ name has been trusted by naval fleets, offshore platform operators, and port authorities worldwide.

Types of Marine Buoys Offered

Mooring Buoy Systems

Mooring buoys are used to anchor vessels in place without the need for traditional pier docking. These buoys feature steel cores and reinforced lifting eyes, with optional fittings such as quick-release shackles or chain-through designs. They are produced in various sizes and buoyancy ratings to support vessels ranging from small boats to large commercial ships. Marine Fenders International offers both T-top and PE-top options. The construction allows the mooring buoy to absorb vessel movement while remaining stable under significant load.

Anchor Buoys

Anchor buoys are essential for marking the positioning of anchors on the bottom of the ocean floor. These buoys are primarily used for:

- Anchor Recovery: If the anchor chain parts or the anchor gets stuck, the buoy marks where to dive or drag to recover the anchor

- Anchor Position Reference: Shows the crew exactly where their anchor is relative to the boat’s position

- Fouling Prevention: Helps prevent other vessels from anchoring too close or dragging across your anchor line

Construction and Use These buoys are brightly colored floats connected to the anchor with an anchor line. The line should be long enough to reach the surface even at high tide, but not so long that it creates a hazard for passing boats.

Distinction from Other Maritime Buoys This is different from mooring buoys (permanent installations for tying up boats) or navigational buoys (aids to navigation). The term “anchor buoy” specifically denotes the small marker buoys used by individual vessels to mark their own anchors.

Some boaters don’t use anchor buoys due to concerns about the buoy line becoming fouled by other boats’ propellers, but they remain standard practice in many anchoring situations, especially in areas with strong currents or rocky bottoms where anchor recovery might be challenging.

Specialized Waterway Buoys

In addition to standard models, Marine Fenders International offers several other waterway buoys that are frequently used in waterway applications:

- Chain Through Buoy

- Cylindrical Buoy

- Universal Buoy

- Navigation Buoy

- Oceanographic Buoy

- Pendant Buoy

- Support Buoy

These waterway buoys are commonly used in waterway applications for marking boundaries, guiding vessel traffic, or supporting marine operations. Many of these models can be customized with hardware, reflective tape, and specific color markings to meet project and regulatory requirements.

Engineering & Performance Features

- Closed-cell foam core prevents water absorption and keeps the buoy afloat even if damaged

- Elastomer outer skin resists UV rays, marine growth, fuel exposure, and abrasion

- Steel core construction provides structural strength for hardware attachments

- Durable materials reduce maintenance needs over time

- Optional fittings include swivels, pad eyes, solar lights, and quick-release hardware

- Available in multiple sizes, including buoys over 10 feet in diameter

- Custom dimensions and configurations can match specific project requirements

Deployment Examples

Marine Fenders International’s buoys have been deployed by U.S. Navy bases, international ports, offshore drilling platforms, and scientific research groups. Projects include mooring systems for cruise terminals, marker buoys for restricted zones, and support buoys for oceanographic equipment. These deployments demonstrate the company’s ability to meet operational requirements in varied marine conditions.

Certifications & Quality Standards

Our products are manufactured in accordance with U.S. Navy and U.S. Coast Guard specifications. Internal quality controls and performance testing are conducted through independent labs when required. This process supports consistent product reliability across large-scale and mission-critical projects.

Contact Marine Fenders International

For more information on sizing, technical specifications, or custom configurations, customers can contact us today. Engineering support is available to assist with selection based on load ratings, dimensions, or project-specific demands.